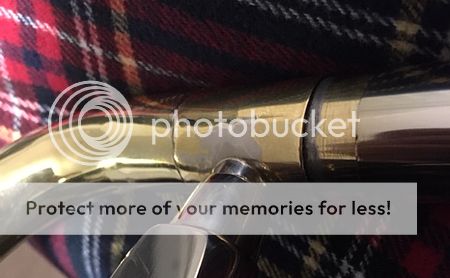

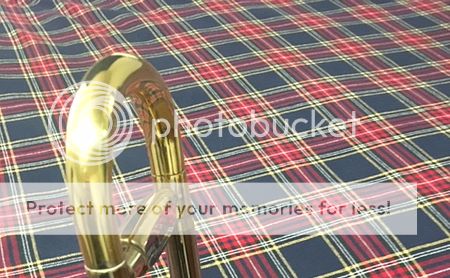

Looking closely at the slide crook, it has a slightly different hue of silver and looks to me as though it is also nickel-plated instead of nickel-silver.

What I find most interesting is that I have read/heard more than a few discussions about how this horn sounds vs how it *should* sound with these components constructed of nickel-silver. Knowing now that they are actually yellow brass potentially explains a lot.

All that being said. (Thanks for letting me geek out there) I’m not really digging the ‘calico’ look and am considering doing some home nickel plating on the tuning slide, which is pretty safe and simple with basic ingredients, and a dc power source. I’ve never done horn parts, though, anyone have any DIY experience with nickel plating on yellow brass horn tubing?