Cleaning a Yamaha rotary valve

-

Bach5G

- Posts: 2516

- Joined: Sat Apr 07, 2018 6:10 pm

Cleaning a Yamaha rotary valve

I’m going to have a go at disassembling and cleaning the valves on my Yam bass. I took it in to the shop in July but now the 2nd valve is sticking again. There’s the cost, but also, in this time of Covid, it takes a week or two, given they wait a minimum of 5 days before they open the case.

Can anyone tell me what tools I will need? A small wooden mallet. What else? And can anyone point me towards a Youtube video or posting that explains how to do this?

Can anyone tell me what tools I will need? A small wooden mallet. What else? And can anyone point me towards a Youtube video or posting that explains how to do this?

- ArbanRubank

- Posts: 424

- Joined: Sat Feb 23, 2019 7:50 am

- Location: Pittsburgh, PA

Re: Cleaning a Yamaha rotary valve

BurgerBob explains it on YouTube. That's what the link below is.

Last edited by ArbanRubank on Thu Sep 10, 2020 2:32 pm, edited 1 time in total.

-

Elow

- Posts: 1879

- Joined: Mon Mar 02, 2020 6:18 am

Re: Cleaning a Yamaha rotary valve

Is it the rotor or all the linkages? Try putting some heavy-ish oil on anything that moves and see if it helps. I had the same problem until i some key oil on my Gb lever’s rod where the spring is.

-

Bach5G

- Posts: 2516

- Joined: Sat Apr 07, 2018 6:10 pm

- noordinaryjoe

- Posts: 95

- Joined: Mon Jul 06, 2020 10:01 am

- Location: Northeast PA

Re: Cleaning a Yamaha rotary valve

Yamaha YBL-612R II

YSL-651

Schiller Heritage Bb/C (YSL-350C clone)

Pirate

YSL-651

Schiller Heritage Bb/C (YSL-350C clone)

Pirate

-

Elow

- Posts: 1879

- Joined: Mon Mar 02, 2020 6:18 am

Re: Cleaning a Yamaha rotary valve

My bad, yamahas use string still don’t they? Burgerbobs video is good, i’m sure edwards has a video too. Valves aren’t too complicated to take apart, but make sure to take a picture of how the string is. My first french horn reassembly took about an hour of just trial and error on trying to get the string to work.

-

Bach5G

- Posts: 2516

- Joined: Sat Apr 07, 2018 6:10 pm

Re: Cleaning a Yamaha rotary valve

Mechanical linkage on my horn (620G).

-

tbonesullivan

- Posts: 1617

- Joined: Tue Jul 02, 2019 9:06 am

- Location: New Jersey

- Contact:

Re: Cleaning a Yamaha rotary valve

Yamaha moved to mechanical linkages on their professional line in the 1990s. I have three Yamahas, and all have mechanical linkages.

I do need to possibly source some parts for one horn.

I do need to possibly source some parts for one horn.

David S. - daveyboy37 from TTF

Bach 39, LT36B, 42BOF & 42T, King 2103 / 3b, Kanstul 1570CR & 1588CR, Yamaha YBL-612 RII, YBL-822G & YBL-830, Sterling 1056GHS Euphonium,

Livingston Symphony Orchestra NJ - Trombone

Bach 39, LT36B, 42BOF & 42T, King 2103 / 3b, Kanstul 1570CR & 1588CR, Yamaha YBL-612 RII, YBL-822G & YBL-830, Sterling 1056GHS Euphonium,

Livingston Symphony Orchestra NJ - Trombone

-

Bonearzt

- Posts: 747

- Joined: Thu Mar 22, 2018 7:40 am

- Location: My Dungeon of Hell....Actually Texas

- Contact:

Re: Cleaning a Yamaha rotary valve

Whatcha need?tbonesullivan wrote: ↑Thu Sep 10, 2020 2:46 pm Yamaha moved to mechanical linkages on their professional line in the 1990s. I have three Yamahas, and all have mechanical linkages.

I do need to possibly source some parts for one horn.

Eric

Eric Edwards

Professional Instrument Repair

972.795.5784

"If you must choose between two evils, choose the one you haven't tried yet."

"Rather fail with honor than succeed by fraud." -Sophocles

Professional Instrument Repair

972.795.5784

"If you must choose between two evils, choose the one you haven't tried yet."

"Rather fail with honor than succeed by fraud." -Sophocles

-

tbonesullivan

- Posts: 1617

- Joined: Tue Jul 02, 2019 9:06 am

- Location: New Jersey

- Contact:

Re: Cleaning a Yamaha rotary valve

I've gotta see if the "Eb Paddle" I have can be bent back into place. A previous owner on my 613H bass had it bent clockwise so it was farther from the handslide brace. They may have bent the linkage, but the paddle was definitely bent.

Thankfully the previous owner DID include the G crook and Gb Crook, so don't need to worry about finding one of those...

David S. - daveyboy37 from TTF

Bach 39, LT36B, 42BOF & 42T, King 2103 / 3b, Kanstul 1570CR & 1588CR, Yamaha YBL-612 RII, YBL-822G & YBL-830, Sterling 1056GHS Euphonium,

Livingston Symphony Orchestra NJ - Trombone

Bach 39, LT36B, 42BOF & 42T, King 2103 / 3b, Kanstul 1570CR & 1588CR, Yamaha YBL-612 RII, YBL-822G & YBL-830, Sterling 1056GHS Euphonium,

Livingston Symphony Orchestra NJ - Trombone

-

Bonearzt

- Posts: 747

- Joined: Thu Mar 22, 2018 7:40 am

- Location: My Dungeon of Hell....Actually Texas

- Contact:

Re: Cleaning a Yamaha rotary valve

Definitely remove it from the horn before you try to bend it!

You can use 2 box end wrenches to give yourself a bit more leverage, but you may gouge the surface a bit.

Eric

You can use 2 box end wrenches to give yourself a bit more leverage, but you may gouge the surface a bit.

Eric

Eric Edwards

Professional Instrument Repair

972.795.5784

"If you must choose between two evils, choose the one you haven't tried yet."

"Rather fail with honor than succeed by fraud." -Sophocles

Professional Instrument Repair

972.795.5784

"If you must choose between two evils, choose the one you haven't tried yet."

"Rather fail with honor than succeed by fraud." -Sophocles

-

tbonesullivan

- Posts: 1617

- Joined: Tue Jul 02, 2019 9:06 am

- Location: New Jersey

- Contact:

Re: Cleaning a Yamaha rotary valve

Definitely. I think they linkage may have been bent slightly too.

Thankfully, it's the EXACT same part as on my other bass. So I can swap them to see how things turn out.

I'm trying to figure out how they managed to bend it like they did without mangling it.

David S. - daveyboy37 from TTF

Bach 39, LT36B, 42BOF & 42T, King 2103 / 3b, Kanstul 1570CR & 1588CR, Yamaha YBL-612 RII, YBL-822G & YBL-830, Sterling 1056GHS Euphonium,

Livingston Symphony Orchestra NJ - Trombone

Bach 39, LT36B, 42BOF & 42T, King 2103 / 3b, Kanstul 1570CR & 1588CR, Yamaha YBL-612 RII, YBL-822G & YBL-830, Sterling 1056GHS Euphonium,

Livingston Symphony Orchestra NJ - Trombone

-

Bonearzt

- Posts: 747

- Joined: Thu Mar 22, 2018 7:40 am

- Location: My Dungeon of Hell....Actually Texas

- Contact:

Re: Cleaning a Yamaha rotary valve

Sometimes a quick hard knock will bend things without you really knowing until later.tbonesullivan wrote: ↑Fri Sep 11, 2020 4:53 pm

Definitely. I think they linkage may have been bent slightly too.

Thankfully, it's the EXACT same part as on my other bass. So I can swap them to see how things turn out.

I'm trying to figure out how they managed to bend it like they did without mangling it.

Eric Edwards

Professional Instrument Repair

972.795.5784

"If you must choose between two evils, choose the one you haven't tried yet."

"Rather fail with honor than succeed by fraud." -Sophocles

Professional Instrument Repair

972.795.5784

"If you must choose between two evils, choose the one you haven't tried yet."

"Rather fail with honor than succeed by fraud." -Sophocles

-

Bach5G

- Posts: 2516

- Joined: Sat Apr 07, 2018 6:10 pm

Re: Cleaning a Yamaha rotary valve

I found a wooden mallet at a Michael’s. In the leatherworks section.

-

tbonesullivan

- Posts: 1617

- Joined: Tue Jul 02, 2019 9:06 am

- Location: New Jersey

- Contact:

Re: Cleaning a Yamaha rotary valve

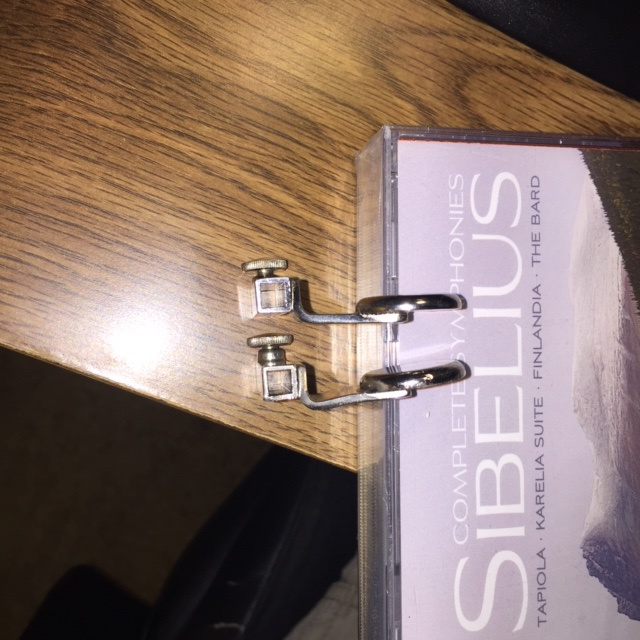

True, but steel is pretty hard to bend like this, and I don't see any damage or bending to the linkage or pivot points. I'm just trying to figure out how they bent it without deforming the square slot for the trigger arm.

The one on the bottom is the one that is bent. I can't tell if the three parts are welded together, or soldered.

David S. - daveyboy37 from TTF

Bach 39, LT36B, 42BOF & 42T, King 2103 / 3b, Kanstul 1570CR & 1588CR, Yamaha YBL-612 RII, YBL-822G & YBL-830, Sterling 1056GHS Euphonium,

Livingston Symphony Orchestra NJ - Trombone

Bach 39, LT36B, 42BOF & 42T, King 2103 / 3b, Kanstul 1570CR & 1588CR, Yamaha YBL-612 RII, YBL-822G & YBL-830, Sterling 1056GHS Euphonium,

Livingston Symphony Orchestra NJ - Trombone

-

Bonearzt

- Posts: 747

- Joined: Thu Mar 22, 2018 7:40 am

- Location: My Dungeon of Hell....Actually Texas

- Contact:

Re: Cleaning a Yamaha rotary valve

That piece IS actually 3 parts brazed together and then plated.

The flat piece connecting the finger pad to the square receiver part is pretty susceptible to bending, as a flat piece of metal like that isn't very stiff in that orientation.

So I am not surprised it bent!

Eric

The flat piece connecting the finger pad to the square receiver part is pretty susceptible to bending, as a flat piece of metal like that isn't very stiff in that orientation.

So I am not surprised it bent!

Eric

Eric Edwards

Professional Instrument Repair

972.795.5784

"If you must choose between two evils, choose the one you haven't tried yet."

"Rather fail with honor than succeed by fraud." -Sophocles

Professional Instrument Repair

972.795.5784

"If you must choose between two evils, choose the one you haven't tried yet."

"Rather fail with honor than succeed by fraud." -Sophocles

-

timothy42b

- Posts: 1609

- Joined: Tue Mar 27, 2018 5:51 am

- Location: central Virginia

- elmsandr

- Posts: 1085

- Joined: Fri Mar 23, 2018 2:43 pm

- Location: S.E. Michigan

- Contact:

Re: Cleaning a Yamaha rotary valve

Unfortunately, it isn't steel. It is brass. Probably not even half-hard brass at that. AND as Eric noted, it was placed in usage where you get no geometric stiffness from the shape of the bend. They could have added a little corner bend in the middle of that like you find in stampings to keep the stiffness, but alas... not much engineering takes place on musical instruments.tbonesullivan wrote: ↑Mon Sep 14, 2020 8:41 pm ...

True, but steel is pretty hard to bend like this, and I don't see any damage or bending to the linkage or pivot points. I'm just trying to figure out how they bent it without deforming the square slot for the trigger arm.

Cheers,

Andy

-

tbonesullivan

- Posts: 1617

- Joined: Tue Jul 02, 2019 9:06 am

- Location: New Jersey

- Contact:

Re: Cleaning a Yamaha rotary valve

Ok. We've got some nice flat faced copper padded bench vises here at work, so I'll see if it can be gently persuaded with plastic mallet. I can see the two areas where it is bent, one near the "Pad" and one near the pivot. It's not that far out of where I want it.Bonearzt wrote: ↑Mon Sep 14, 2020 9:28 pm That piece IS actually 3 parts brazed together and then plated.

The flat piece connecting the finger pad to the square receiver part is pretty susceptible to bending, as a flat piece of metal like that isn't very stiff in that orientation.

So I am not surprised it bent!

Eric

David S. - daveyboy37 from TTF

Bach 39, LT36B, 42BOF & 42T, King 2103 / 3b, Kanstul 1570CR & 1588CR, Yamaha YBL-612 RII, YBL-822G & YBL-830, Sterling 1056GHS Euphonium,

Livingston Symphony Orchestra NJ - Trombone

Bach 39, LT36B, 42BOF & 42T, King 2103 / 3b, Kanstul 1570CR & 1588CR, Yamaha YBL-612 RII, YBL-822G & YBL-830, Sterling 1056GHS Euphonium,

Livingston Symphony Orchestra NJ - Trombone

-

Bonearzt

- Posts: 747

- Joined: Thu Mar 22, 2018 7:40 am

- Location: My Dungeon of Hell....Actually Texas

- Contact:

Re: Cleaning a Yamaha rotary valve

I would recommend using padded pliers or similar to coax that piece back into position rather than tapping with a mallet. Better control this way!tbonesullivan wrote: ↑Tue Sep 15, 2020 7:25 amOk. We've got some nice flat faced copper padded bench vises here at work, so I'll see if it can be gently persuaded with plastic mallet. I can see the two areas where it is bent, one near the "Pad" and one near the pivot. It's not that far out of where I want it.Bonearzt wrote: ↑Mon Sep 14, 2020 9:28 pm That piece IS actually 3 parts brazed together and then plated.

The flat piece connecting the finger pad to the square receiver part is pretty susceptible to bending, as a flat piece of metal like that isn't very stiff in that orientation.

So I am not surprised it bent!

Eric

Eric Edwards

Professional Instrument Repair

972.795.5784

"If you must choose between two evils, choose the one you haven't tried yet."

"Rather fail with honor than succeed by fraud." -Sophocles

Professional Instrument Repair

972.795.5784

"If you must choose between two evils, choose the one you haven't tried yet."

"Rather fail with honor than succeed by fraud." -Sophocles

-

tbonesullivan

- Posts: 1617

- Joined: Tue Jul 02, 2019 9:06 am

- Location: New Jersey

- Contact:

Re: Cleaning a Yamaha rotary valve

Good point! We've got those too. The hardest part is getting it to bend at the location you want it to bend. Second hardest: not breaking it.

David S. - daveyboy37 from TTF

Bach 39, LT36B, 42BOF & 42T, King 2103 / 3b, Kanstul 1570CR & 1588CR, Yamaha YBL-612 RII, YBL-822G & YBL-830, Sterling 1056GHS Euphonium,

Livingston Symphony Orchestra NJ - Trombone

Bach 39, LT36B, 42BOF & 42T, King 2103 / 3b, Kanstul 1570CR & 1588CR, Yamaha YBL-612 RII, YBL-822G & YBL-830, Sterling 1056GHS Euphonium,

Livingston Symphony Orchestra NJ - Trombone

-

Bonearzt

- Posts: 747

- Joined: Thu Mar 22, 2018 7:40 am

- Location: My Dungeon of Hell....Actually Texas

- Contact:

Re: Cleaning a Yamaha rotary valve

Yup...tbonesullivan wrote: ↑Tue Sep 15, 2020 12:49 pmGood point! We've got those too. The hardest part is getting it to bend at the location you want it to bend. Second hardest: not breaking it.

Eric Edwards

Professional Instrument Repair

972.795.5784

"If you must choose between two evils, choose the one you haven't tried yet."

"Rather fail with honor than succeed by fraud." -Sophocles

Professional Instrument Repair

972.795.5784

"If you must choose between two evils, choose the one you haven't tried yet."

"Rather fail with honor than succeed by fraud." -Sophocles

- elmsandr

- Posts: 1085

- Joined: Fri Mar 23, 2018 2:43 pm

- Location: S.E. Michigan

- Contact:

Re: Cleaning a Yamaha rotary valve

Good thing you already have two!

Question for the group; Is the leading cause of just using the bare rod for trigger without the paddle:

A) It falling off because of the lousy screw.

B) Trying to fix them when they bend and breaking it completely.

I know for me it is 100% B.

Cheers,

Andy

Question for the group; Is the leading cause of just using the bare rod for trigger without the paddle:

A) It falling off because of the lousy screw.

B) Trying to fix them when they bend and breaking it completely.

I know for me it is 100% B.

Cheers,

Andy

-

tbonesullivan

- Posts: 1617

- Joined: Tue Jul 02, 2019 9:06 am

- Location: New Jersey

- Contact:

Re: Cleaning a Yamaha rotary valve

True, but I also have two trombones that use them, so swapping would be annoying.

I've seen SO many used bass trombones lacking the finger paddle. Also so many that require massive adjustments. One of the reasons I went for a Yamaha for my 2nd bass is because i find their system to be the best out there in terms of being adjustable. It can work whether you use a regular grip, or a Yeo-style grip, and it just works. It feels secure.

I also one time did try to bend a paddle on a tenor and that taught me never to try that again. With this though, I think I can do it carefully without messing it up, and if I do, well, I can just order a new one.

David S. - daveyboy37 from TTF

Bach 39, LT36B, 42BOF & 42T, King 2103 / 3b, Kanstul 1570CR & 1588CR, Yamaha YBL-612 RII, YBL-822G & YBL-830, Sterling 1056GHS Euphonium,

Livingston Symphony Orchestra NJ - Trombone

Bach 39, LT36B, 42BOF & 42T, King 2103 / 3b, Kanstul 1570CR & 1588CR, Yamaha YBL-612 RII, YBL-822G & YBL-830, Sterling 1056GHS Euphonium,

Livingston Symphony Orchestra NJ - Trombone

-

tbonesullivan

- Posts: 1617

- Joined: Tue Jul 02, 2019 9:06 am

- Location: New Jersey

- Contact:

Re: Cleaning a Yamaha rotary valve

looking closely at the paddle now, I can see the tell tale row of parallel lines from a pair of pliers. Very faint, but definitely there. Going to look at it later today, and hopefully not destroy it.

David S. - daveyboy37 from TTF

Bach 39, LT36B, 42BOF & 42T, King 2103 / 3b, Kanstul 1570CR & 1588CR, Yamaha YBL-612 RII, YBL-822G & YBL-830, Sterling 1056GHS Euphonium,

Livingston Symphony Orchestra NJ - Trombone

Bach 39, LT36B, 42BOF & 42T, King 2103 / 3b, Kanstul 1570CR & 1588CR, Yamaha YBL-612 RII, YBL-822G & YBL-830, Sterling 1056GHS Euphonium,

Livingston Symphony Orchestra NJ - Trombone

-

tbonesullivan

- Posts: 1617

- Joined: Tue Jul 02, 2019 9:06 am

- Location: New Jersey

- Contact:

Re: Cleaning a Yamaha rotary valve

I used some hand pressure in a padded vise, as well as an adjustable crescent wrench. The "support" for the paddle did not want to straighten out though, so I had to use a brass drift on it a bit. Put some marks on one side, but I'm quite happy with the end results.

David S. - daveyboy37 from TTF

Bach 39, LT36B, 42BOF & 42T, King 2103 / 3b, Kanstul 1570CR & 1588CR, Yamaha YBL-612 RII, YBL-822G & YBL-830, Sterling 1056GHS Euphonium,

Livingston Symphony Orchestra NJ - Trombone

Bach 39, LT36B, 42BOF & 42T, King 2103 / 3b, Kanstul 1570CR & 1588CR, Yamaha YBL-612 RII, YBL-822G & YBL-830, Sterling 1056GHS Euphonium,

Livingston Symphony Orchestra NJ - Trombone

-

Bonearzt

- Posts: 747

- Joined: Thu Mar 22, 2018 7:40 am

- Location: My Dungeon of Hell....Actually Texas

- Contact:

Re: Cleaning a Yamaha rotary valve

Nice!!

Eric Edwards

Professional Instrument Repair

972.795.5784

"If you must choose between two evils, choose the one you haven't tried yet."

"Rather fail with honor than succeed by fraud." -Sophocles

Professional Instrument Repair

972.795.5784

"If you must choose between two evils, choose the one you haven't tried yet."

"Rather fail with honor than succeed by fraud." -Sophocles

-

tbonesullivan

- Posts: 1617

- Joined: Tue Jul 02, 2019 9:06 am

- Location: New Jersey

- Contact:

Re: Cleaning a Yamaha rotary valve

And it still fits! I was worried I had possibly deformed the channel. Now I just need to find time to give the 613H a full cleaning. I don't think I'll pull the rotors at this time, but maybe he next time around.

David S. - daveyboy37 from TTF

Bach 39, LT36B, 42BOF & 42T, King 2103 / 3b, Kanstul 1570CR & 1588CR, Yamaha YBL-612 RII, YBL-822G & YBL-830, Sterling 1056GHS Euphonium,

Livingston Symphony Orchestra NJ - Trombone

Bach 39, LT36B, 42BOF & 42T, King 2103 / 3b, Kanstul 1570CR & 1588CR, Yamaha YBL-612 RII, YBL-822G & YBL-830, Sterling 1056GHS Euphonium,

Livingston Symphony Orchestra NJ - Trombone

-

Bach5G

- Posts: 2516

- Joined: Sat Apr 07, 2018 6:10 pm